Description

Dock Leveler

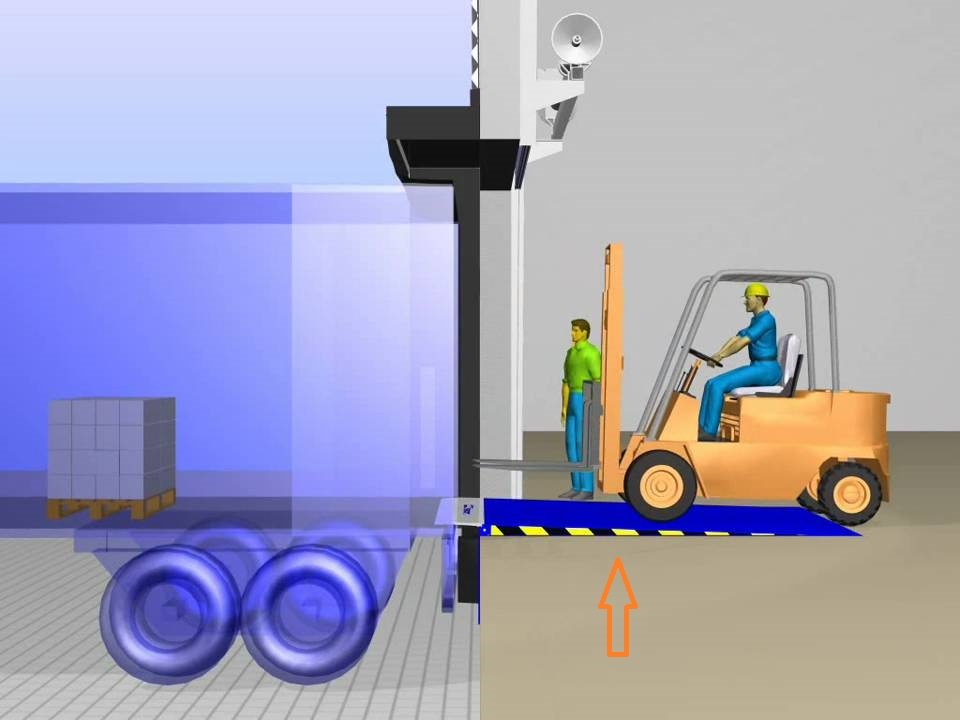

Dock Leveler is known as Dock Ramp or Loading Ramp, which is widely used in loading bays of logistics centers, warehouses, and dispatch areas of factories. In most cases, the container floor of the truck will not be on the same level as the loading bay floor. And this lead to that, forklifts or trolley can not be used to load or unload goods into container. It will take much labor to move the goods by hand. This will be very low efficient.

But with an automatic dock leveler, such a problem with be solved perfectly. The stationary fixed dock leveler will be placed into a pre-built concrete pit on the loading bay. A hydraulic motor drives the platform up and down, realizing a seamless joint between room ground and truck floor. Then, forklifts or trolleys can transfer goods quickly on the dock leveler platform. Thus it improves the loading & unloading efficiency obviously and also saves much labor.

3D View

Advantages

Our dock leveler quality is oriented as premium high quality with medium price. So it will save costs and energy for clients long term. It can keep working for more than 15 years without big maintenance.

Important Points:

1. Enough thickness of steel plate at both platform and front lip. 12mm-16mm.

2. We add a strong support structure made by steel tubes under the platform, to make the platform much stronger. Thus it can withstand the big weight and will avoid bending.

3. Top brand hydraulic motor and hydraulic pump system.

4. High-quality control panel with electricity overrun protection and accident power-failure protection.

Standard Parts

Our standard dock leveler includes below three parts:

1. Main Body: Well assembled.

2. Control Panel: It should be mounted on the inside wall, for operating the leveler.

3. Dock Bumper: Elastic rubber material. It is to protect both loading bay and truck by avoiding big direct collisions.

FEATURES

Features:

1. The overall assembly can bear 120% load of standard nominal load capacity. Under static pressure of 24 hours, the deformation is within 3mm. And after pressure released , the deformation will recover.

2. Platform ground is made from high-strength 8mm or above thick steel plate. Surface is processed with groove milling to make it anti-skid.

3. Hinge and Shaft , are Super-High-Temperature heat treated, to reduce its deformation

4. Whole set of hydraulic drive station is made by us under supervision of highly qualified professionals . It can work under high frequency because of very low work temperature of oil. High standard seal avoids oil leaking.

5. Surface treatment:Coated with Red Oxide and Enamel Paint, very durable and high anti-corrosive.

Technical Data:

| Power supply: |

1-phase 220±10%V,50/60HZ, or 3-380V±10%V,50/60HZ |

| Loading capacity: |

6000KG/10000KG/15000KG |

| Adjusting scope: |

-300mm to +350mm |

| Power of motor: |

0.75KW-2.2KW |

| Standard size: |

2000*2000*500 (can be customized) |

Size Table:

| Dock Leveler Size |

Pit Size |

| 2000*1800*500 |

2000*1830*510 |

| 2000*2000*500 |

2000*2030*510 |

| 2500*2000*500 |

2500*2030*510 |

| Customized |

Customized |

Above sizes of dock leveler are mostly adopted in different projects. For special situations, we can customize the size according to actual requirement.